Fahnen Kössinger, 25.05.2016 um 09:25 Uhr

Printed flags - this is how the color is applied to the fabric

The motive for the new flag is completely designed, the suitable fabric chosen - now, the printing can start. But how to apply the color to the fabric? Basically, two different techniques have asserted themselves: silk screen and digital printing. Both processes have their advantages, depending on the application of the flag, the quantity, and the motive.Silk screen printing

Simply said, the motive here is transferred to the fabric by using a screen.

This screen consists of a water permeable sieve made of capillary mesh that is put into a tight frame. In a first step, a light sensitive layer is put onto this mesh that consists of polyester or metal fibers. This layer is exposed to light so that the motive becomes visible. Only the light exposed spaces are permeable for the color. The finished photo-emulsion is tentered over the flag fabric. The color is being distributed with a special tool called squeegee or blade. It permeates onto the fabric at the respective places. Per working step, only one color can be applied, therefore, for each color, a separate screen has to be made.

This screen consists of a water permeable sieve made of capillary mesh that is put into a tight frame. In a first step, a light sensitive layer is put onto this mesh that consists of polyester or metal fibers. This layer is exposed to light so that the motive becomes visible. Only the light exposed spaces are permeable for the color. The finished photo-emulsion is tentered over the flag fabric. The color is being distributed with a special tool called squeegee or blade. It permeates onto the fabric at the respective places. Per working step, only one color can be applied, therefore, for each color, a separate screen has to be made.

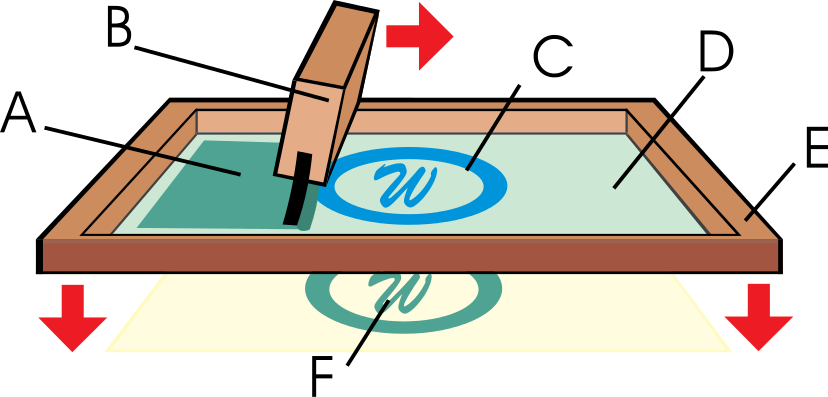

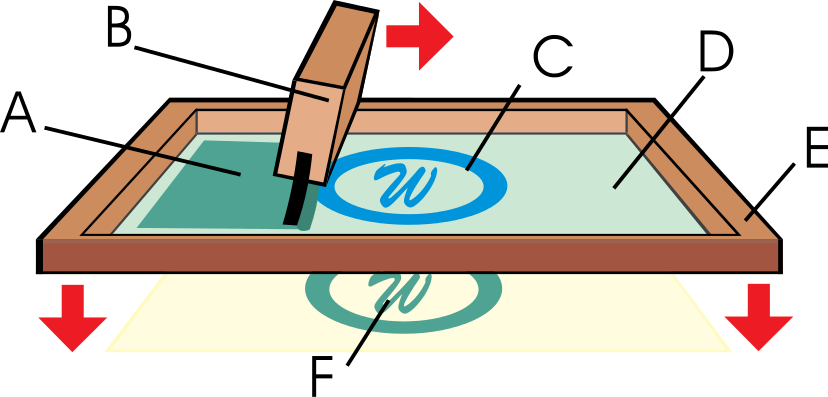

Schematic presentation of the screen printing procedure:

A. Ink. B. Squeegee. C. Image. D. Photo-emulsion. E. Screen. F. Printed image

A. Ink. B. Squeegee. C. Image. D. Photo-emulsion. E. Screen. F. Printed image

Quelle: https://en.wikipedia.org/wiki/Screen_printing

A. Ink. B. Squeegee. C. Image. D. Photo-emulsion. E. Screen. F. Printed image

A. Ink. B. Squeegee. C. Image. D. Photo-emulsion. E. Screen. F. Printed imageQuelle: https://en.wikipedia.org/wiki/Screen_printing

The preparations for screen printing are thus very laborious. But once the respective photo-emulsions are ready, bigger quantities can be printed comparatively quickly and cheaply.

Apart from that, screen printing has another advantage: The colors can be designed more individually than with other printing processes. Because one color is applied per each photo-emulsion, this color can be mixed in advance already. If an exact color such as the blue of the European Union is desired or the color should shine at night, such wishes can be fulfilled with screen printing. In order to save labor, however, one often works with the basic colors CMYK (cyan, magenta, yellow, and black). Here, the screens for each basic color are made that only let the necessary amount of color permeate at the respective places. Thus, often only four screens are necessary for printing a photo, e.g., if need be complemented by a couple of special colors.

Apart from that, screen printing has another advantage: The colors can be designed more individually than with other printing processes. Because one color is applied per each photo-emulsion, this color can be mixed in advance already. If an exact color such as the blue of the European Union is desired or the color should shine at night, such wishes can be fulfilled with screen printing. In order to save labor, however, one often works with the basic colors CMYK (cyan, magenta, yellow, and black). Here, the screens for each basic color are made that only let the necessary amount of color permeate at the respective places. Thus, often only four screens are necessary for printing a photo, e.g., if need be complemented by a couple of special colors.

Digital printing

For this technique, a printer is used that is also known from home offices: The color printer is directly controlled by the computer, there is no production of an artwork necessary. Just as with the known ink jet printer, the color is directly applied onto the fabric. The printer mixes the colors according to the motive out of the basic colors. This means on the one hand that motives consisting of small parts can be printed with a better resolution than with alternative processes, because the color is directly transferred and the structure of the photo-emulsion is not important. But on the other hand, clearly defined, exact color wishes cannot be fulfilled as well as with silk screen printing. If the color has to be defined exactly, digital printing is at a disadvantage.

The most important advantage of digital printing, however, is the cheap production of single pieces, e.g. personalised clothing. Apart from that, it works quicker as many work steps are omitted. Some specialists meanwhile suppose that digital printing will one day completely replace other procedures.

After the printing, the colors are being fixated in both cases. By treating them for instance with hot steam, they deeply permeate the filaments. The motive thus becomes visible on the backside. Only then, the flag is ready for usage.

back to the blog survey >

After the printing, the colors are being fixated in both cases. By treating them for instance with hot steam, they deeply permeate the filaments. The motive thus becomes visible on the backside. Only then, the flag is ready for usage.

back to the blog survey >

English

English  Deutsch

Deutsch