Fahnen Kössinger – keeping tradition alive

Conserving the old, we create new things and thus save cultural goods for the following generations. Traditional hand and machine embroidery in highest artistry meets individual, timeless design while taking care of positioning parts of the pictures and texts in a way to form a big ensemble and make the used colors and material to emanate a harmonious total.We gladly invite you to a little company tour through our flag embroidery.

1

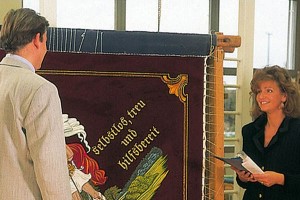

Discussion

Most of the time, our customers come to us with precise ideas, hand us photos and motives in and tell us which inscriptions they want on both sides of the new flag. During an extensive meeting with them we converse about how to transfer our customers' imaginations into the optimal design, material, and embroidery techniques.

Most of the time, our customers come to us with precise ideas, hand us photos and motives in and tell us which inscriptions they want on both sides of the new flag. During an extensive meeting with them we converse about how to transfer our customers' imaginations into the optimal design, material, and embroidery techniques.

2

An artwork is generated

At first, the embroideries are diligently drawn. Our experienced graphic designers produce their artful sketches with skillful hand on parchment paper. IN case there are still some insecurities about the overall design, our drawing artists make a provisional small sketch that already includes all details but still allows amendments, if necessary.

At first, the embroideries are diligently drawn. Our experienced graphic designers produce their artful sketches with skillful hand on parchment paper. IN case there are still some insecurities about the overall design, our drawing artists make a provisional small sketch that already includes all details but still allows amendments, if necessary.

3

Complete artwork

Together with the texts and the crest, a complete artwork develops out of the drawn sketch. It is made in original size and, in the further course of production, it serves as a model for the embroiderers. It already conveys a good impression to our customers about the afterwards finished flag, as texts and motives are already at their correct place.

Together with the texts and the crest, a complete artwork develops out of the drawn sketch. It is made in original size and, in the further course of production, it serves as a model for the embroiderers. It already conveys a good impression to our customers about the afterwards finished flag, as texts and motives are already at their correct place.

4

Transfering the artwork

The so-called plotter that had already drawn the artwork in original size onto the parchment, now perforates the outlines by using fine needles. The embroiderers diligently align the artwork on the chosen flag fabrics and copy the outlines by using a peculiar liquid that drips through the holes onto the fabric. For smooth materials, a special tracing paper is used.

The so-called plotter that had already drawn the artwork in original size onto the parchment, now perforates the outlines by using fine needles. The embroiderers diligently align the artwork on the chosen flag fabrics and copy the outlines by using a peculiar liquid that drips through the holes onto the fabric. For smooth materials, a special tracing paper is used.

5

Shiny applications

The writings and ornaments that were drawn onto the flag fabric according to the graphic artwork are now put on by the hand embroiderer in finest detailed handiwork. She uses litz wire, smooth or frizzly frisé or cantille with real guilding for the golden and silver ornaments. Thus, precious artworks in highest perfection develop in long hours of most diligent and detailed work.

The writings and ornaments that were drawn onto the flag fabric according to the graphic artwork are now put on by the hand embroiderer in finest detailed handiwork. She uses litz wire, smooth or frizzly frisé or cantille with real guilding for the golden and silver ornaments. Thus, precious artworks in highest perfection develop in long hours of most diligent and detailed work.

6

Mechanical handiwork

For this kind of embroidery, machines are used that partly date back to the 19th century, amongst others from the well-known enterprise Cornely. They look like normal sewing machines but allow free movement of the fabric below the needle. It is easy to understand why one talks of "needle painting" during the development of an embroidered picture when looking over an embroiderer's shoulder.

For this kind of embroidery, machines are used that partly date back to the 19th century, amongst others from the well-known enterprise Cornely. They look like normal sewing machines but allow free movement of the fabric below the needle. It is easy to understand why one talks of "needle painting" during the development of an embroidered picture when looking over an embroiderer's shoulder.

7

Drop stitch universal feed embroidery

The drop stitch universal feed embroidery is a special kind of machine embroidery. It is used to execute chain or cord stitches. Amongst others, they are used to reinforce worn fabrics if, during a restoration, one doesn't want to replace the whole background. In our flag embroidery, we master all important embroidery techniques for new flags and restoration.

The drop stitch universal feed embroidery is a special kind of machine embroidery. It is used to execute chain or cord stitches. Amongst others, they are used to reinforce worn fabrics if, during a restoration, one doesn't want to replace the whole background. In our flag embroidery, we master all important embroidery techniques for new flags and restoration.

8

Stretching

Same as with smaller embroideries, also the big-sized flag that is being embroidered has to be stretched into a tenterframe. Otherwise, the fabric would be constricted by the tightening of the embroidery threads and get folds. That's why the fabric gets a lining of nettle cloth at first and is then evenly spread and stretched all around into a wooden frame.

Same as with smaller embroideries, also the big-sized flag that is being embroidered has to be stretched into a tenterframe. Otherwise, the fabric would be constricted by the tightening of the embroidery threads and get folds. That's why the fabric gets a lining of nettle cloth at first and is then evenly spread and stretched all around into a wooden frame.

9

Steaming

Just by their dense structure with fluffy filaments, high tuft velvets create a very noble and precious impression. By putting pressure on the velvet during transport or storage, uncomely pressure marks develop that appear dull and flat. By steaming with water vapor, these pressure marks in the velvet are removed and its structure re-established.

Just by their dense structure with fluffy filaments, high tuft velvets create a very noble and precious impression. By putting pressure on the velvet during transport or storage, uncomely pressure marks develop that appear dull and flat. By steaming with water vapor, these pressure marks in the velvet are removed and its structure re-established.

10

Finishing

Only in the end are the two flag sides sewn together. Still, both parts are each stretched in their respective tenter frame and are aligned exactly back to back. The rims have to be equally wide all around, the flag in a correct angle. Now, the seamstresses can attach the fringes and hanging loops to the finished flag.

Only in the end are the two flag sides sewn together. Still, both parts are each stretched in their respective tenter frame and are aligned exactly back to back. The rims have to be equally wide all around, the flag in a correct angle. Now, the seamstresses can attach the fringes and hanging loops to the finished flag.

11

Final inspection

As a matter of course, each flag is being inspected thoroughly before it is handed over to our customer. Are all threads properly sewn, the motives and writings correctly done, all accessory parts prepared? Not the slightest uncleanliness must disturb the overall picture so that our customers can proudly present their new club flag to the public.

As a matter of course, each flag is being inspected thoroughly before it is handed over to our customer. Are all threads properly sewn, the motives and writings correctly done, all accessory parts prepared? Not the slightest uncleanliness must disturb the overall picture so that our customers can proudly present their new club flag to the public.

12

The flag consecration can begin!

In the course of a solemn ceremony, the flag is being consecrated in a church. Befriended clubs, patron clubs and numerous visitors from the surroundings gather to admire the precious piece and celebrate a festivity together with the proud club which will be spoken of for quite some time still. Fahnen Kössinger also supplies the necessary accessories for the festival.

In the course of a solemn ceremony, the flag is being consecrated in a church. Befriended clubs, patron clubs and numerous visitors from the surroundings gather to admire the precious piece and celebrate a festivity together with the proud club which will be spoken of for quite some time still. Fahnen Kössinger also supplies the necessary accessories for the festival.

English

English  Deutsch

Deutsch